World-Class Mining Technology

Consulting, Training and Support

Providing assistance at every stage of the mining technology life cycle

Step 1: Planning

Helping you select the correct technologies for your prospective mining operation. Selecting the most appropriate technology and infrastructure during the infancy of a mining operation is critical for long-term success. Embracing technological advancements in the feasibility study stage isn't just about staying ahead of the curve; it's about laying the foundation for a financially sound, environmentally responsible, scalable, and ultimately successful mining project.

MTS Services Include:

RFI for Operational Technology

RFP for Operational Technology

Operational Technology Tendering Technical Assistance

Technology Roadmap Development

Step 2: Implementation

Integrating new technology with your operations to ensure a maximised return on investment. We don't just implement new technology; we embed it directly into your operation’s daily workflows and processes to ensure it delivers value. This covers services including installation validation, change management and customised site training.

MTS Services Include:

Implementation Assistance

Change Management

OT Organisation Structure Development

Network Coverage Studies

Custom Site Training

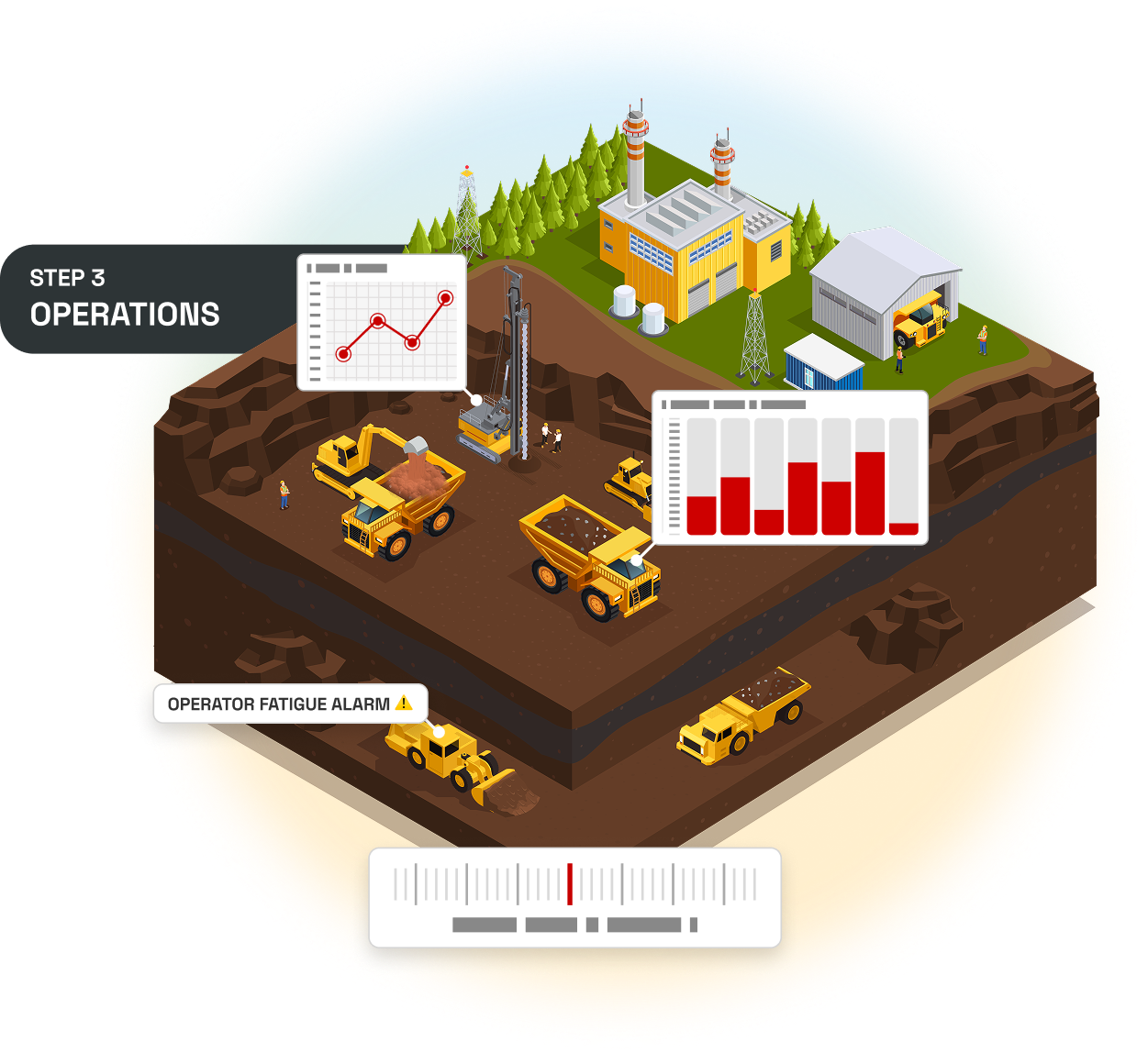

Step 3: Operations

Enhance your mining operations with the power of data and technology. During a mine’s operational stage, our focus is on leveraging new or existing technology to enhance productivity, safety, and environmental footprints. We address all aspects of mining operations, encompassing surface, underground, and maintenance activities; optimising operations through services including optimisation assessments, custom dashboards and refresher technology training.

MTS Services Include:

Surface Operations Mining Technology Assessment

Underground Operations Mining Technology Assessment

Dashboarding and Automated Reports

Refresher Technology Training

Data Driven Optimisation Studies

Data Driven Environmental Assessments

Maintenance Technology Assistance

See more information on package solutions here

CONSULTANCY SERVICES

Mining Technology Assessments

Mining technology assists mines in enhancing safety, boosting productivity, lowering costs, and effectively managing or reducing energy consumption. Despite this, many mines overlook its full potential. Our independent, comprehensive, and data-driven assessments examine how effectively an operation is using mining technology to support its needs. Based on these evaluations, we offer practical recommendations to boost technology usage. Recommendations are integrated into a personalised roadmap tailored to each mine’s unique operations, maturity, business goals, and budget constraints. Click here to speak to one of the MTS team about our mining technology assessments.

Click here to see our packages which we can tailor to your site’s needs.

Operational Assessments

Through a combination of onsite study and data analysis, our approach provides a comprehensive assessment of your mining operation’s performance. Unlike traditional consultancies that primarily rely on observations and anecdotal evidence, our expertise in mining systems and data allows us to delve much deeper. This enables us to offer unique insights and perspectives that often differ from conventional approaches. Our assessments aim to help you identify opportunities for improvement, including enhancing safety, increasing productivity, improving mobile asset reliability, optimising recoveries, and reducing CO2 emissions. Click here to speak to one of the MTS team about our operational assessments.

Click here to see our packages which we can tailor to your site’s needs.

Feasibility Studies: Operational Technology Roadmap

Selecting the right technology and infrastructure during the early stages of a mining operation is crucial for long-term success. Many feasibility studies neglect this aspect, leading to last-minute technology purchases or generic options that may not align with the specific requirements of the operation. This approach can result in cost inefficiencies and technological complexities, negatively impacting the financial viability, environmental sustainability, and scalability of the mining project. Click here to speak to one of the MTS team about how we can assist during the feasibility stage.

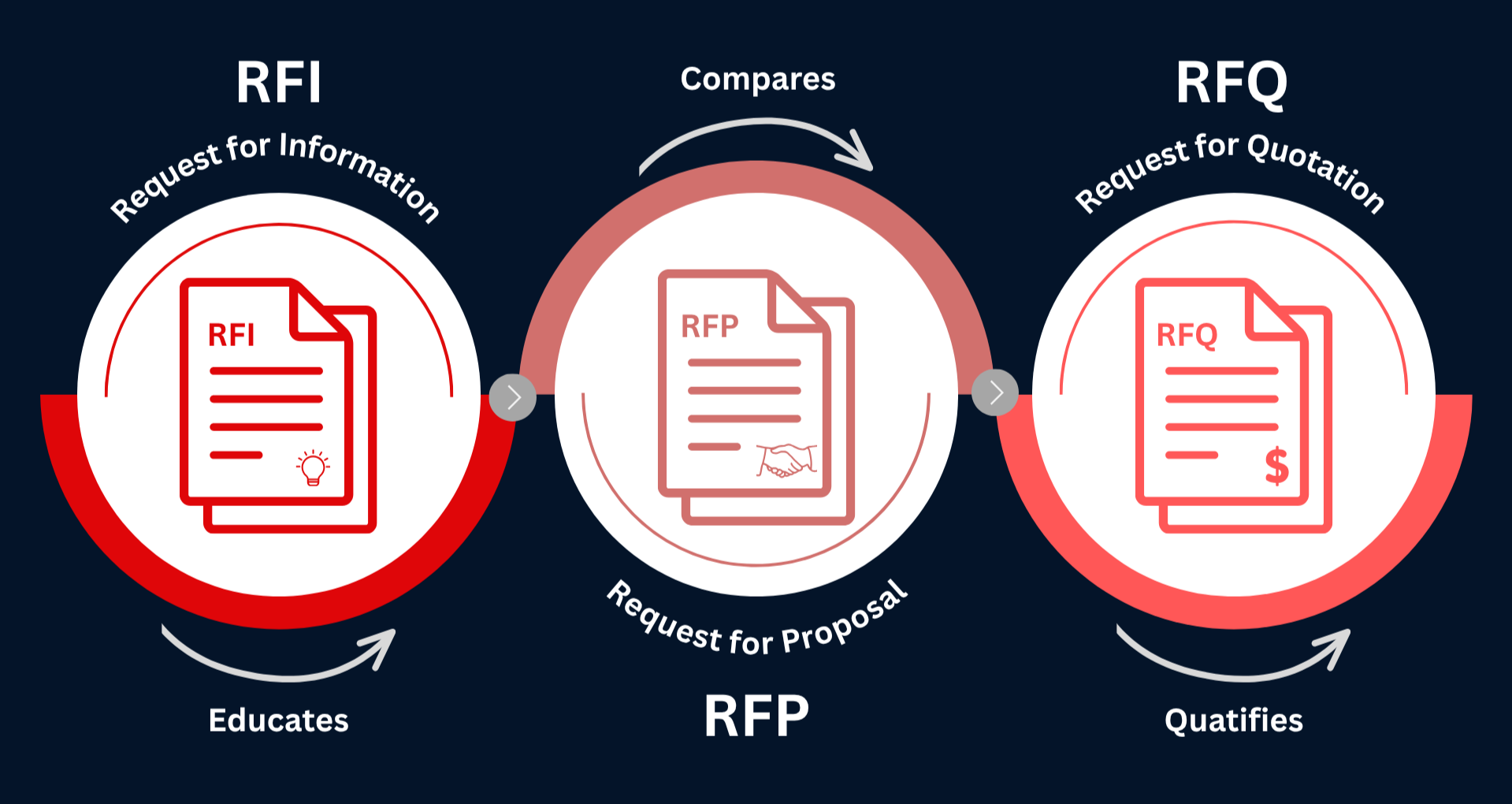

Mining Technology RFI/RFQ Selection Support

Mining technology selection is challenging, with mines often lacking independent advice before making expensive, time-consuming, and potentially operation-changing purchases. MTS helps operations choose the right technology by studying your operation so a full picture of all operational needs and challenges is understood. We provide unbiased assessments of mining technologies and assist with the development and management of requests for information (RFIs) and requests for quotations (RFQs). Click here to speak to one of the MTS team about how we can help you choose the right technology the first time around.

ANALYTICS SERVICES

Data Analytics and Business Intelligence Solutions

Our data engineering team harnesses the power of complex mining datasets to extract valuable insights. We transform these insights into captivating and user-friendly visuals that resonate with audiences. Our interactive dashboards provide long-term monitoring capabilities, allowing decision-makers to monitor key performance indicators (KPIs) and make informed decisions. By leveraging existing tools like Power BI, Grafana, or Tableau, we reduce costs and enhance long-term support. In the past 10 years we have developed 100s of dashboarding solutions for mining short interval control, asset health, mine planning and more. Click here to speak to one of the MTS team about our beautifully crafted solutions.

Bespoke Custom Software

At MTS, we understand the limitations of off-the-shelf mining software, particularly in cross-system integrations. Our expertise lies in crafting custom software solutions that seamlessly plug these gaps. Our robust and cost-effective solutions empower mining operations to overcome these challenges and achieve their unique objectives. Our mining-experienced software developers and data engineers have a decade of experience creating customised solutions for a wide range of areas including asset health and equipment reliability, mining operations and more. Click here to speak to one of the MTS team about how we can ease some of the pain!

SUPPORT SERVICES

Targeted Training & Mentoring

We provide comprehensive training and mentoring packages tailored to the specific needs of your mining team including dispatchers/controllers, operators, pit crews, supervisors, data engineers, mining engineers, and site administrators. Our team of experienced mining technologists delivers customized training sessions that cover fleet management systems, asset health reporting, and other critical systems. Whether you're looking to enhance your current skills or acquire new knowledge, our bespoke training solutions are designed to optimise your mining operations and drive success. Click here to speak to one of the MTS team about how we can give your team a boost.

Mining Tech Support

At MTS, we recognize the complexity of mining technology and the challenges faced by busy onsite personnel. With years of experience in supporting mines with technology, we offer an additional layer of support beyond what may be unavailable from software vendors or within the mine itself. Our mining tech experts guide smooth implementation, minimizing risks and maximizing results, helping to avoid overruns, reskilling needs, and change resistance. Click here to speak to one of the MTS team.

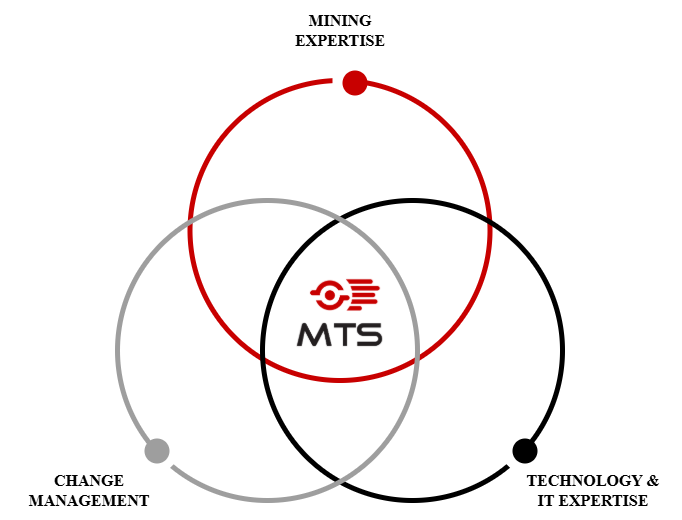

Why Choose MTS for your Mining Technology Needs?

At MTS, we bridge the gap between mining technology, people, and IT. Our experienced team of mining technologists is dedicated to empowering mines to enhance productivity, minimise waste, and optimise costs through the seamless integration of technology.

Why Choose MTS for your Mining Technology Needs?

At MTS, we bridge the gap between mining technology, people, and IT. Our experienced team of mining technologists is dedicated to empowering mines to enhance productivity, minimise waste, and optimise costs through the seamless integration of technology.