Measuring What Matters: Updating Time Usage Models for the Modern Mine

Accounting for the impact of operational technology on mining downtime?

In the world of mining, every minute counts. The Time Usage Model (TUM) helps operations understand how equipment spends its time, categorising it into productive work, maintenance down, or various delays. The goal is to maximise the productivity of each required piece of equipment’s working time - without pointlessly running every available machine! As mining becomes more technology-dependent, the traditional TUM is being challenged and may no longer fully capture modern operational reality.

The Pillars of a Traditional TUM

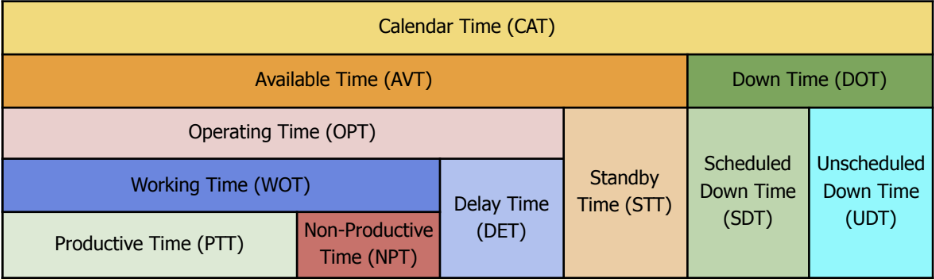

The foundation of most time usage models is a clear hierarchy that breaks down a calendar period into distinct categories. The Global Mining Group (GMG) framework, for example, starts with the below but they admit that their model doesn’t really cover downtime in any detail.:

Calendar Time (CT) which progressively divides it into smaller, more specific time blocks typically including items such as.

Available Time (AT): This is when equipment is ready to perform its function.

Operating Time (OT): The period when the equipment is available and under the control of a human or system.

Downtime (DT): The time when equipment is required but unable to operate due to maintenance or other issues. Capturing the scheduled versus unscheduled downtime is a significant performance indicator for any maintenance department.

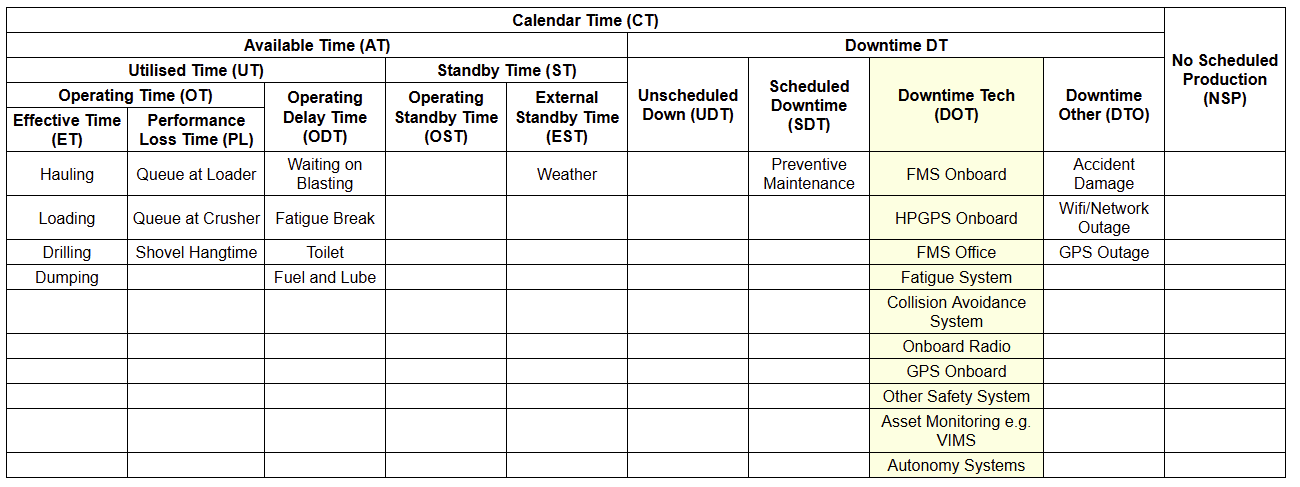

Time usage models inevitably vary from site to site; with factors such as OEM MARC contracts often being an additional complexity. Examples are shown below:

This structured approach is essential for calculating key performance indicators (KPIs) across the organisation, that are universally understood and used to help guide the business. There are many potential high-level metrics that can calculated from the TUM such as Availability, Utilisation and Operating Efficiency, as well as more targeted metrics such as Mean Time Between Failure (MTBF), Mean Time to Repair (MTTR), which are more common for the reliability team. Sites normally agree on a set and they form the basis for many discussions, scorecards etc.

The Tech Revolution and the TUM's Ticking Clock

A significant rise in the (serious) use of Operational Technology (OT) including Autonomous Haulage Systems (AHS), Fleet Management Systems (FMS), Collision Avoidance and Fatigue Detection has introduced a new layer of complexity. These systems are not part of the machine's core mechanical, hydraulic or electrical function, yet their failure can bring operations to a halt for safety, productivity or regulatory reasons. At a minimum the failure of an Operational Technology will reduce the effectiveness of the assets operation.

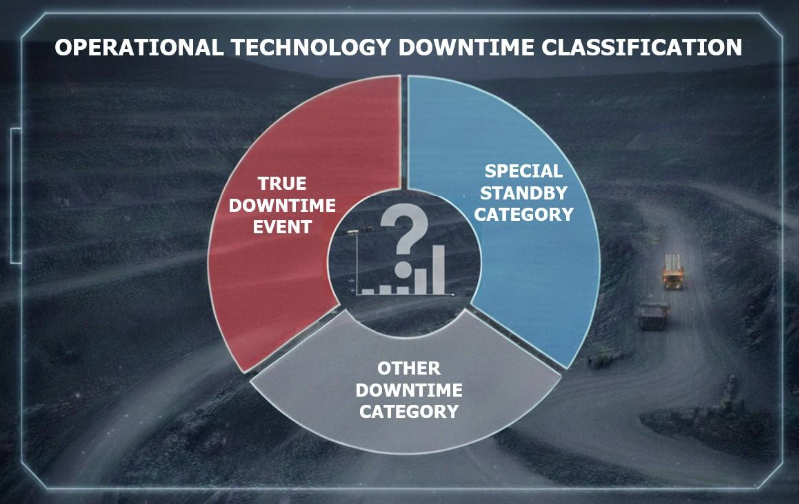

Who is responsible for each of these items, as well as dependent infrastructure, can often fall between different departments with few metrics in place or associated owners. The allocation of Operational Technology down time is hotly debated as a result of this. A discussion with a group of mining technology professionals about how to classify the downtime associated with these systems highlighted very different views on this topic.

A central point of debate is whether a technology failure should be classified as a true downtime event, a standby period, or a new separate category entirely.

Some argue that if a system is required by site regulations or company standards for effective production, its failure is a functional failure, and the equipment should be classified as down. This would give an urgency to get this issue resolved as with any down, and any shortfall in skills or tools would aim to be resolved.

Others suggested mining technology failures should be contained within an "Other Down Time" category with dedicated codes allocated for items such as the Fleet Management System (FMS), High Precision GPS machine guidance (HPGPS) or Wi-Fi networks. This approach allows for separate tracking of technology reliability without penalising the maintenance department for issues outside their control.

The discussion also brought up the need to create new KPIs that measure technology reliability and operational impact, suggesting that an updated TUM could provide a clearer picture of the costs and benefits of modern mining technology.

The Path Forward: Adapting the TUM for Technology

The consensus from these discussions is clear: the Time Usage Model must evolve for sites using OT at their operations. Simply lumping technology failures into a general downtime category is no longer sufficient. A modern TUM should incorporate new classifications that:

Isolate Technology Downtime: Create distinct categories or sub-categories to capture technology-related issues, providing a clear picture of their frequency and duration. For example, “Downtime - Technology” or “Downtime - Other”.

Redefine Metrics: Adjust traditional KPIs like availability and MTBF to account for technology-specific downtime, preventing misrepresentation of mechanical performance.

Drive Improvement: The data collected from these new classifications can be used to justify resources for technology maintenance and plan for proactive upkeep, moving beyond a reactive approach.

The GMG has acknowledged this need for change and is in the process of reviewing and updating its Time Usage Model, a promising sign that the industry is moving towards a more accurate and comprehensive framework that embraces the complexities of modern, tech-driven mining operations.

What KPIs could be utilised?

To measure mining technology onboard maintenance performance, we typically look at time to stoppage as well as total downtime hours due to technology-related issues. Examples include:

“Mean Time Between Technology Related Stoppage” (MTBS-Tech) = Operating Hours/Technology Related Stoppage Count

Technology Downtime Hours = Sum of all downtime hours where the down code/”delay type” is mining technology-related.

We also like KPIs related to “time between mining technology PM inspection”......this really helps to drive a world class, more proactive approach to the upkeep of the onboard kit.

As a final note on KPIs, we’d always suggest the technology related stoppages do not end up “diluting” the wrong department’s metrics. So for example, if the maintenance team do not maintain the tech, then the technology related bucket (i.e. “Unscheduled Down - Tech”) should be excluded from availability calculations.

Summary: A Modernised TUM

The traditional Time Usage Model is inadequate for modern, technology-intensive mining operations. It fails to capture a significant source of production loss: downtime caused by Operational Technology failures. A revised framework must formally categorise technology-related downtime and introduce specific Key Performance Indicators to measure its impact. This precise classification is necessary to accurately assess system reliability, direct maintenance resources effectively, and achieve continuous improvement in asset availability and production goals.